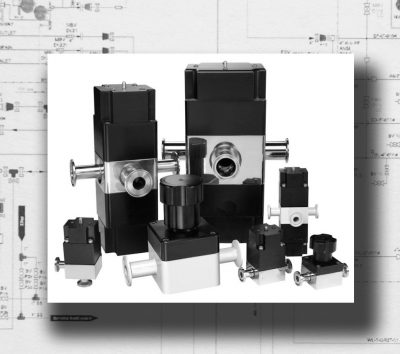

ABOUT DELCO SANITARY VALVES

Delco’s sanitary valves:

- Meet all critical specifications for aseptic processing

- Exceed requirements for durability and cost-effective production

- Is cleaner the Weir-style valve

- Eliminates the risk of contamination

- Is a million-cycle diaphragm

- Durable in steam applications

- Provides the cleanest flow path

- Eliminates hold-up volume.

- Machined of solid Teflon

- Lasts considerably longer than reconstituted diaphragm

- Continuously self-cleaning

- Will not entrap process fluids or contaminants

- Two-way and multi-ported

- Allows more compact systems.

- Ideal for fermentation and purification applications

- Provides product purity improvement for the pharmaceutical, biotech, cosmetic, food, beverage, and fine chemical industries.

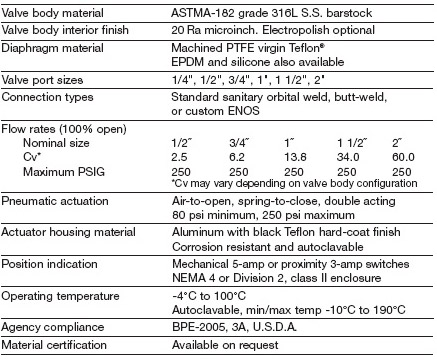

Delco is a proven innovator and reliable source for sanitary valves. All major components are assembled and tested in Delco’s facility in Akron, Ohio. Valve bodies are mechanically polished and electropolished. Delco provides a variety of flow paths and up to six ports to meet all mixing and diverting applications.

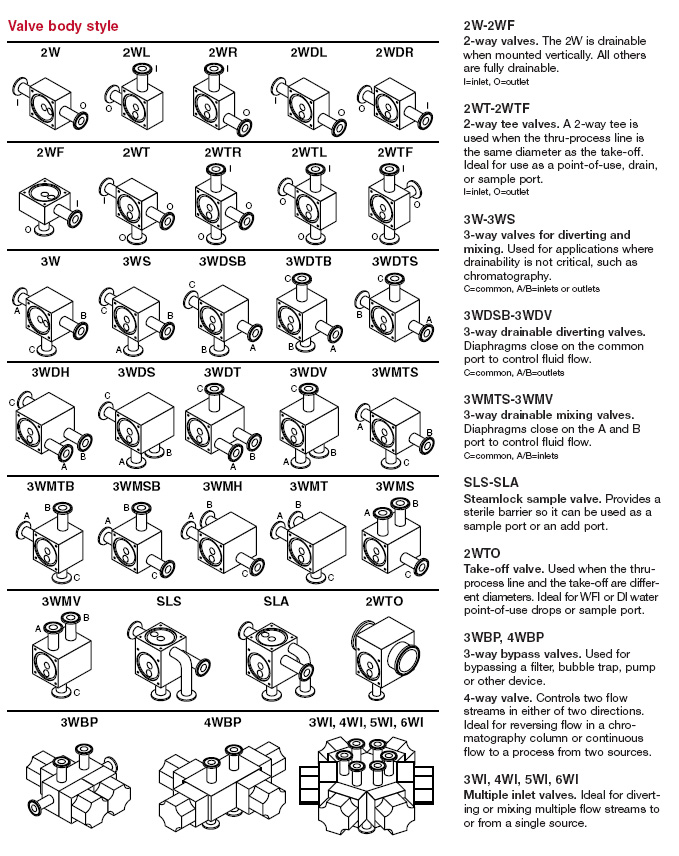

Click here for common flow path options.

Delco is a proven innovator and reliable source for sanitary valves. All major components are assembled and tested in Delco’s facility in Akron, Ohio. Valve bodies are mechanically polished and electropolished. Delco provides a variety of flow paths and up to six ports to meet all mixing and diverting applications.

Delco’s sanitary valves:

- Meet all critical specifications for aseptic processing

- Exceed requirements for durability and cost-effective production

- Is cleaner the Weir-style valve

- Eliminates the risk of contamination

- Is a million-cycle diaphragm

- Durable in steam applications

- Provides the cleanest flow path

- Eliminates hold-up volume.

- Machined of solid Teflon

- Lasts considerably longer than reconstituted diaphragm

- Continuously self-cleaning

- Will not entrap process fluids or contaminants

- Two-way and multi-ported

- Allows more compact systems.

- Ideal for fermentation and purification applications

- Provides product purity improvement for the pharmaceutical, biotech, cosmetic, food, beverage, and fine chemical industries.

DELCO SANITARY VALVES ENSURE

Total Sterilization

All wetter surfaces are continuously cleaned by vortex fluid action. Chamber and diaphragm geometry have no areas to entrap contaminants and are ideal for CIP or SIP.

Long-Life

Solid virgin BTFM Teflon outperforms the reconstituted Teflon of weir-style valves for long service and fewer replacements. The machined diaphragm will not lister or delaminate and has a high cycle life under CIP/SIP cleaning.

Leakproof

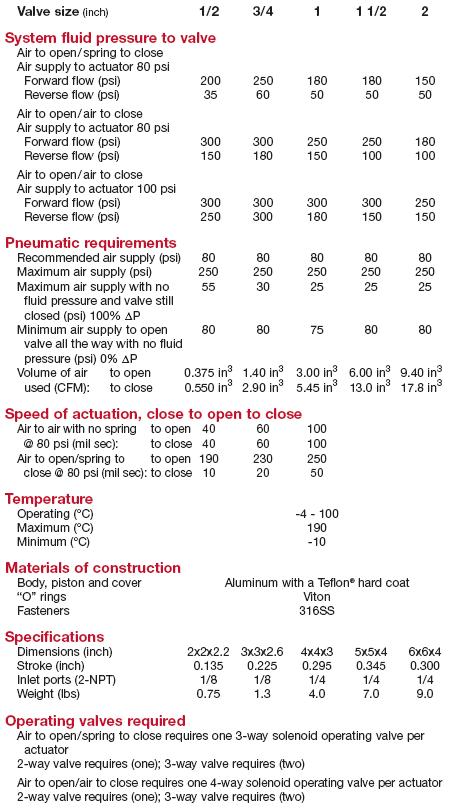

The diaphragm is held in compression for a positive seal and requires less force than a weir style valve. Diaphragm cold flow improves the valve seal and performance. Process fluid is isolated for the actuator and environment.

No Holdup Volume

No holdup volume improves product purity, and an instantaneous flow shift eliminates cross contamination.

DELCO SANITARY VALVES FEATURE

Ideal Applications:

Typical uses include chromatography, filtration, fermentation, media preparation, WFI/DI water preparation, clean-in-place systems; and diverting, in-line mixing, and fluid metering.

Compact Systems:

Small footprint and volume reduce overall system size. Optional porting provides flexibility in system design, and modularity simplifies fabrication.

Custom Fabrication and Configurations:

Up to six ports and special flow paths are available. Options include steam ports, CIP ports, and special purpose features, plus all piping end-connection configurations are available.

Our unique diaphragm valve is specifically engineered to improve the quality and efficiency of sanitary processing systems used in the biopharmaceutical industry.

Delco’s valves are in the 1 million cycle diaphragm for higher operating pressures. Our valves feature drainable, on-off diverting, mixing and fractional collection, and are made of FDA compliant material.

Delco meets the performance requirements of many users of high-purity engineered components and fabricated assemblies.

Learn more about Delco multi-ported valves in clean chromatographic operations and pure water systems.